DEPOT MANAGER

YSG GLOBAL ENERGY CO. LTD

2018 - Present

CALABAR

• Responsible for ensuring strict compliance with the company’s policies and procedures as documented in the company’s manuals and industry standards.

• Active involvement in the commissioning of new deport which goes along with the intensive training of all operation personnel and ensuring all departments are properly set up.

• Upgrade of storage capacity and effective management of product custody transfer, close monitoring of all phases of terminal operations, vessel receipt operation, storage and handling, and all tank to truck operations.

• Responsible for ensuring strict adherence to HSEQ standards and procedures by all depot personnel and visitors, responsible for approving all work permits for contractors and all in-house maintenance activities.

• Effective management of operational gain/loss performance of products and ensure performance are always within the international agreed tolerance level (+/-0.3% Ship to Shore and +/-0.2% Tank to Truck).

• Close monitoring of completed contract projects and checking for compliance with the approved scope of work and agreed quality standard.

• Carry out effective budget planning for the terminal in conformance to the global company plan.

• Careful determination of the appropriate capital projects to embark upon, and presenting proposal to justify reasons for the choices made.

• Responsible for the financial performance and cost control of the operational budget, ensure regular safety training is carried out for all terminal staffs and operators.

• Established a close relation with the external auditors, regulators, quality control bodies to ensure the company runs effectively and within the government approved modus operando.

• Ensure proper and periodic maintenance of terminal equipment’s and carried out as approved.

TERMINAL AMANGER

EMADEB ENERGY SERVICES LTD

2014 - 2018

LAGOS

• Ensured strict compliance with the companies laid down policies and procedures as documented in the company’s manual and industry standard.

• Carried out optimization of the storage capacity and effective management of product custody transfer, effectively managed and monitored all phases of the terminal operation.

• Ensure full compliance with the HSEQ standards by personnel, functioned as the approval authority for all work permit for contractors and in-house maintenance activities.

• Ensured strict adherence to HSEQ standards and procedures by all depot personnel and visitors, responsible for approving all work permits for contractors and all in-house maintenance activities.

• Effective management of operational gain/loss performance of products and ensure performance are always within the international agreed tolerance level (+/-0.3% Ship to Shore and +/-0.2% Tank to Truck).

Project Management Activities:

1. Project cost; ₦ 33,000,000

Project Duration: 3 Months

Project Work; Fabrication of 16†common header line, fabrication of metering skid with all associated accessories installed (Brodie PD Meter, PRV, Pressure gauge, Accolad III.net, Control Valves, Permissive Device), supply and installation of complete SPX Centrifuge pumps with associated electric motors.

Duties: Responsible for project initiation, review, contract evaluation and management, active involvement in terminal expansion projects which includes the installation of additional two complete metering skid with PD meters, digital preset system, strainers and centrifuge pumps (2 x 34KW Electronic Motor &SPX Johnson Pump) completed and operational.

2. Project cost; ₦ 298,345,458,90

Project Duration: 8 Months

Project Design: API 650, EI/JIG Standard 1530

Method Used: Hydraulic Jack up system

Project work: Fabrication and erection of tank, sandblasting to sa2.5, epoxy coating in and out using HAMPADOUR paint, supply and installation of filter water separator vessels, NDT test, Fabrication and installation of cargo and service pipeline 10†and 8†respectively, installation of 8†floating suction in the tank.

PROJECT DESCRIPTION: Construction of additional one above the ground storage steel tank using API 650/ EI/JIG Standard for Jet-A1 (Aviation fuel) storage with capacity of 10,000M3 Tons. This is project has been completed, commissioned and operational. The tank was 30M x 17.5M epoxy painted inside and outside wall, installed with 8†floating suction. Installation of Filter water separator vessel at both upstream and downstream of the cargo and service line.

• Responsible for authorizing daily truck loading programme and effective management of all logistical issues.

• Ensured timely loading of all customers trucks and ensured zero spill, zero fertility, zero fire/explosion incidents, zero demurrage.

• Effectively managed and monitored ship-shore transfer and ensured losses fall within the international accepted limit.

• Management of operating gains/losses and ensured it remains within the international accepted limit.

• Responsible for the financial performance and effective cost control of Opex budget.

• Responsible for the determination of the appropriate Capex project, and presented proposal for justification

• Ensured strict compliance with the companies laid down policies and procedures as documented in our manuals and industry standards.

Project Management Activities:

• Responsible for project initiation, review, contract evaluation and management; Terminal expansion which includes the installation of two skid with loading and centrifuge pups (complete and operational). Construction of additional two which were right above the ground storage steel tank using API650 with capacity 9,000 M3 Ton (Currently on hold)

Terminal Maintenance Management Activities:

• Design of daily, weekly, monthly and yearly maintenance program, and ensure the technicians carry out the assigned program accurately and with safety in mind.

• Carried out a well-planned and cost effective, preventive and breakdown maintenance guidelines for all terminal and office equipment’s.

• Ensured strict compliance with company policies and procedures as documented in the company’s manuals and industry standards.

• Perform regular risk assessment and periodic evaluation of equipment’s and contractors.

• Above the ground steel tank inspection in accordance with API 653, supervision of engineering staffs, company registered contractors and other agreed 3rd party contractors

ASSISTANT MANAGER, PROJECT AND TECHNICAL

MRS POIL & GAS LTD

2010 - 2013

LAGOS

• Carried out various project management activities which includes project design review and project coordination.

• Carried out terminal maintenance management which involved preparation of monthly and yearly maintenance plan for implementation, co-ordinate engineering and maintenance activities to ensure compliance with the company’s processes and laid down policies.

Instrumentation Engineer

MRS Oil and Gas Limited, Apapa, Lagos State. February 2010 – February 2013

• Actively involved in the installation, maintenance, configuration and repair of the instruments within the fuel loading terminal e.g. flow meters, batch controllers, digital valves, pulsars, loading arm e.t.c.

• Actively involved in the commissioning, repair and operations of marine loading arm.

• Carried out pump controls, installation, repair and maintenance of pump relays, repair of Rosemount tank gauging system installed on the storage tank.

• Carefully implemented annual preventive maintenance plan for instrumentation and aviation equipment’s and spares inventory program.

• Identified all broken-down equipment’s and effected immediate repair, closely monitor equipment performance in line with the planned objectives.

• Liaised and supervised third-party contractors to ensure speedy resolution of faulty equipment’s.

• Liaised with JIG/IATA IFQP audit and ensure the audit gaps are closed, also with the procurement department for spare/equipment’s specifications.

• Developed budget estimate, labor cost, material and installation of equipment’s within the terminal, inspect completed installations and observe operations to ensure conformity to design and equipment specifications and compliance with operational and safety standards.

• Gained necessary skills in the programming and maintenance of Alley Bradley (Micrologix) PLC, Siemens PLC and Omron PLC.

• Ensured calibration instruments within the loading depot are carried out in accordance with API and DPR standards.

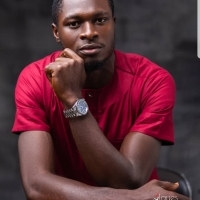

Ameerah Agoro

Ameerah Agoro Oluwayemisi Oladele

Oluwayemisi Oladele  Daniel Nwogbo

Daniel Nwogbo SAMUEL EZEKIEL OKWOCHE

SAMUEL EZEKIEL OKWOCHE Global Services

Global Services Ardova PlC

Ardova PlC shensy funeral services

shensy funeral services  Markatteh Engineering and Cons

Markatteh Engineering and Cons Unmask NG

Unmask NG